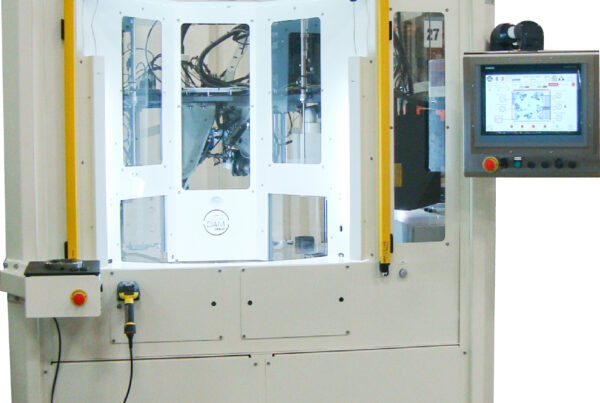

Our mastery of innovative technologies enables us to provide a comprehensive response to our customers’ issues. We develop simple solutions to meet their increasingly complex technical needs.

Our expertise and know-how cover several areas:

As a result of our R&D, we offer our customers easily usable solutions aimed at productivity gains and maintenance optimisation.

KEY FIGURES

- 35

years of expérience

- 70%

turnover at

export

- 60

Employees

- ISO

9001 &

Tisax

- 3000

m2 workshops

- 12

m€ of turnover

Our values

They trust us

Join us!

DAM Group is regularly looking for talent to complete its team of experts! Don’t wait any longer and join us!

SEE JOB OFFERS

SPONTANEOUS APPLICATION

News