COLLABORATIVE SUPPORT FOR THE INDUSTRIALISATION OF PRODUCTION

Home »

Towards industrialisation of production

The industrialisation of a product is necessary for any company, whatever the sectors of activity, regardless of industry: automotive, food industries, etc.

Specialised in industrialisation for 35 years, DAM Group supports its clients throughout the process from the industrialisation phase to the mass production.

We offer innovative solutions thanks to an efficient methodology based on a collaborative approach with our clients:

1. Analysis and definition of the need

- Analysis of the functioning of the product

- Proposal to optimise large-scale industrialisation

- Analysis of the production line needs (speed, flexibility, scalability)

- Definition of the industrial process based on the time/cost/quality constraints

- Setting standards for a coherent and optimised global approach

2. Achievements

- The realisation of an entire turn-key line

- Monitoring the implementation process

- Validation of preliminary projects

- Validation of studies

- Validation of the pre-acceptance

- Validation of the reception

- Documentation of technical files (assembly, inspection, maintenance range, etc.)

LET’S EXPLORE THE RANGE OF POSSIBILITIES TOGETHER

WE MEET YOUR MOST SPECIFIC NEEDS

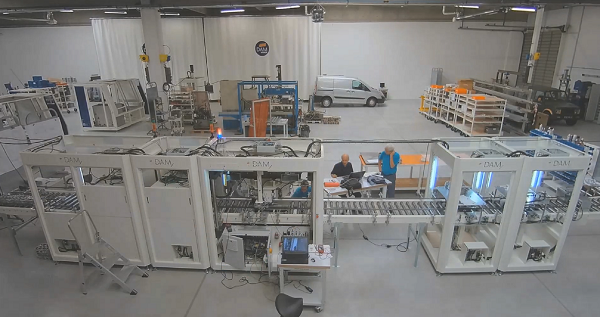

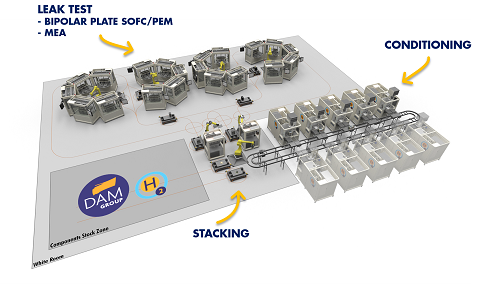

ACHIEVEMENTS