Fuel Cell stack testing and assembly line

How to control & assemble effectively fuel cell stacks for mass production?

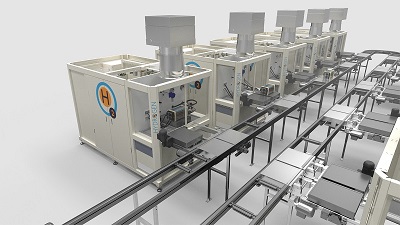

DAM Group designs and manufactures modular and expandable test lines for fuel cell stacks. This is to be as close as possible to our clients current production level while anticipating their future needs.

By offering robust and competitive solutions, DAM Group supports its clients to validate the manufacturing process while optimizing cycle times and therefore manufacturing costs.

The presented design allows an end-of-line control of bipolar plates and membranes in seconds or less, and stacks in minutes, depending on client technical specifications.

Our tailor-made solutions allow or client to focus on their product. The freedom of settings makes it possible to continuously improve its test sequences.

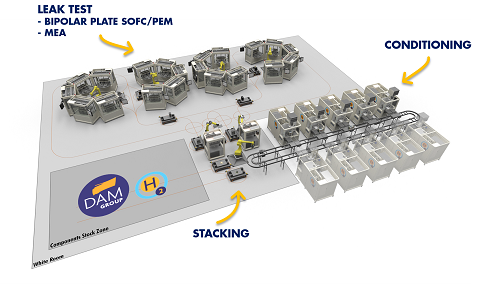

This configuration consists of 3 main parts:

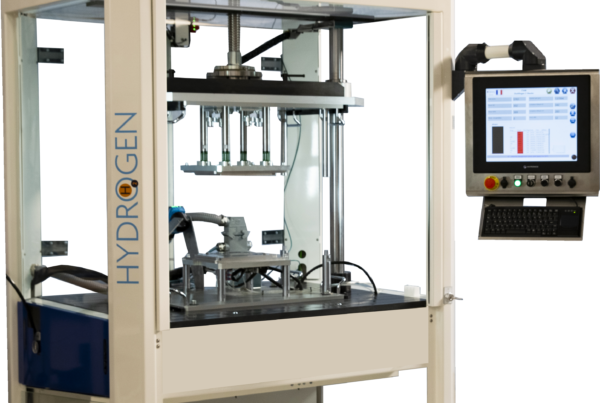

PART 1 : LEAK TEST BENCHES FOR BIPOLAR PLATES AND MEMBRANES

Leak test benches for bipolar plates and membranes with masked time loading and simultaneous testing of several parts allow:

- precise testing

- reducing cycle time

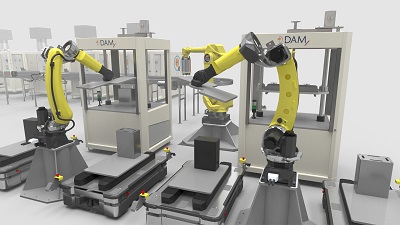

PART 2 : STACKING AREA

The components are assembled and mounted with force control in the stacking area. The assembly is directly after the end-of-line test of the components in order to:

- optimize the supply chain

- limit stock

PART 3 : FUEL CELL STACK CONDITIONING

Once the fuel cell is fully assembled, it each fuel cell system has to be activated. That is to say that for the first time the fuel cell will receive hydrogen and oxygen to create its first electrical watts. This conditioning step is very important because the quality of the conditioning will :

- guarantee the quality of the fuel cell’s operation

- contribute to its longevity over time

Our fuel cell stack conditioning benches are controlled using our software TestAvenue, which allows great freedom of configuration.

In fact, our client can optimize its test sequences autonomously, with or without programming knowledge.

Fuel Cell test Bench for Laboratory

You need to test and validate your products in the design phase and/or your prototypes?

All of our Fuel cell test benches are also designed for your research and development needs.

LET’S EXPLORE THE RANGE OF POSSIBILITIES TOGETHER

WE MEET YOUR MOST SPECIFIC NEEDS

OUR ACHIEVEMENTS