High pressure testing station 400 bar / 875 bar for hydrogen systems

DESCRIPTION

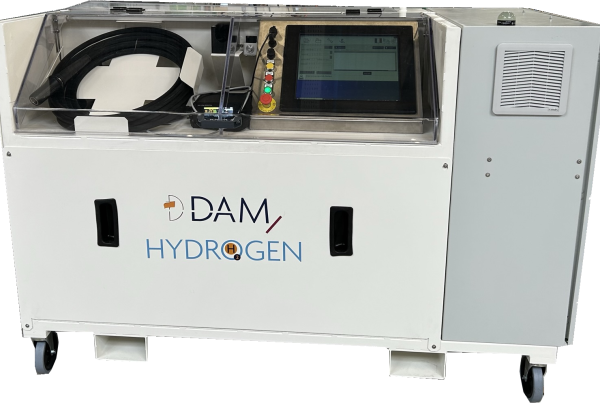

With its expertise in leak testing, DAM Group has developed a unique high pressure leak test solution for hydrogen component assembly.

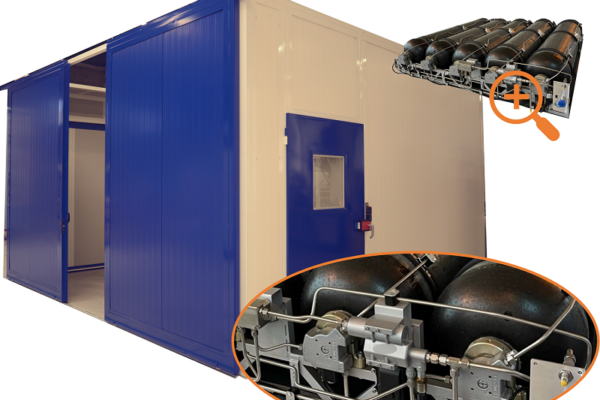

The station allows to control and verify the tightness by a leak test ramping up to 875 bar.

Hydrogen high pressure testing applies to components (tanks, generators, electrolysers, H2 valves) as well as to the high pressure circuits of hydrogen vehicles, such as cars, trucks, vans and trains.

Anticipate the risks, control your high pressure hydrogen systems!

DESCRIPTION

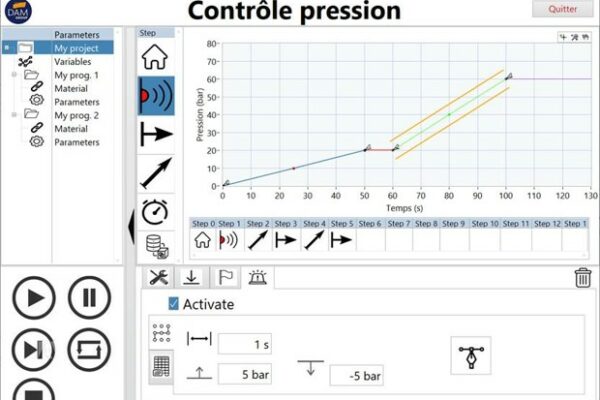

- Validation of the tightness and the pressure resistance

- Leak detection by steps

- 400 bars / 875 bars

- Data backup and complex analysis

- Laboratory and production test bench

- Tested products: tanks, generators, electrolysers, H2 valves, high pressure circuits, H2 vehicles

- Safety of the installations

- Product safety: progressive pressure build-up

- Operator safety

- Measurement :

– Pressure build-up by configurable ramp

– Test repeatability

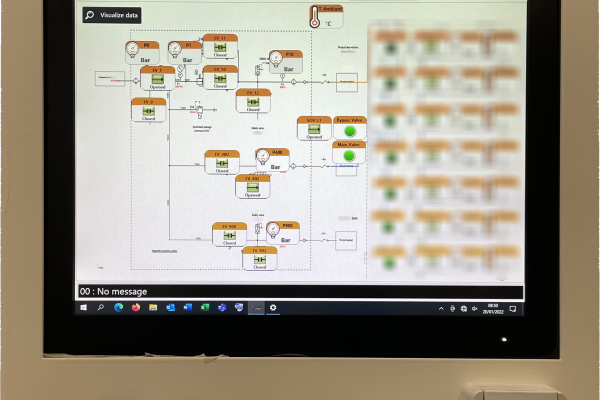

- HMI :

– Direct display of the output pressure

– Display of the history of the last XX tests

– Software configurable by the user

– Data archiving and traceability

- Data communication :

– Ethernet, Modbus TCP/IP

- Services :

After-sales service

Maintenance

- Options :

Filling function possible

Infrared link : SAE J2799 protocol

LET’S EXPLORE THE RANGE OF POSSIBILITIES TOGETHER

WE MEET YOUR MOST SPECIFIC NEEDS

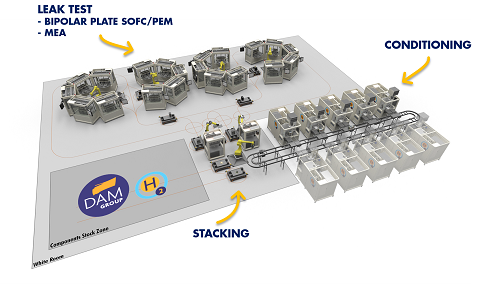

ACHIEVEMENTS